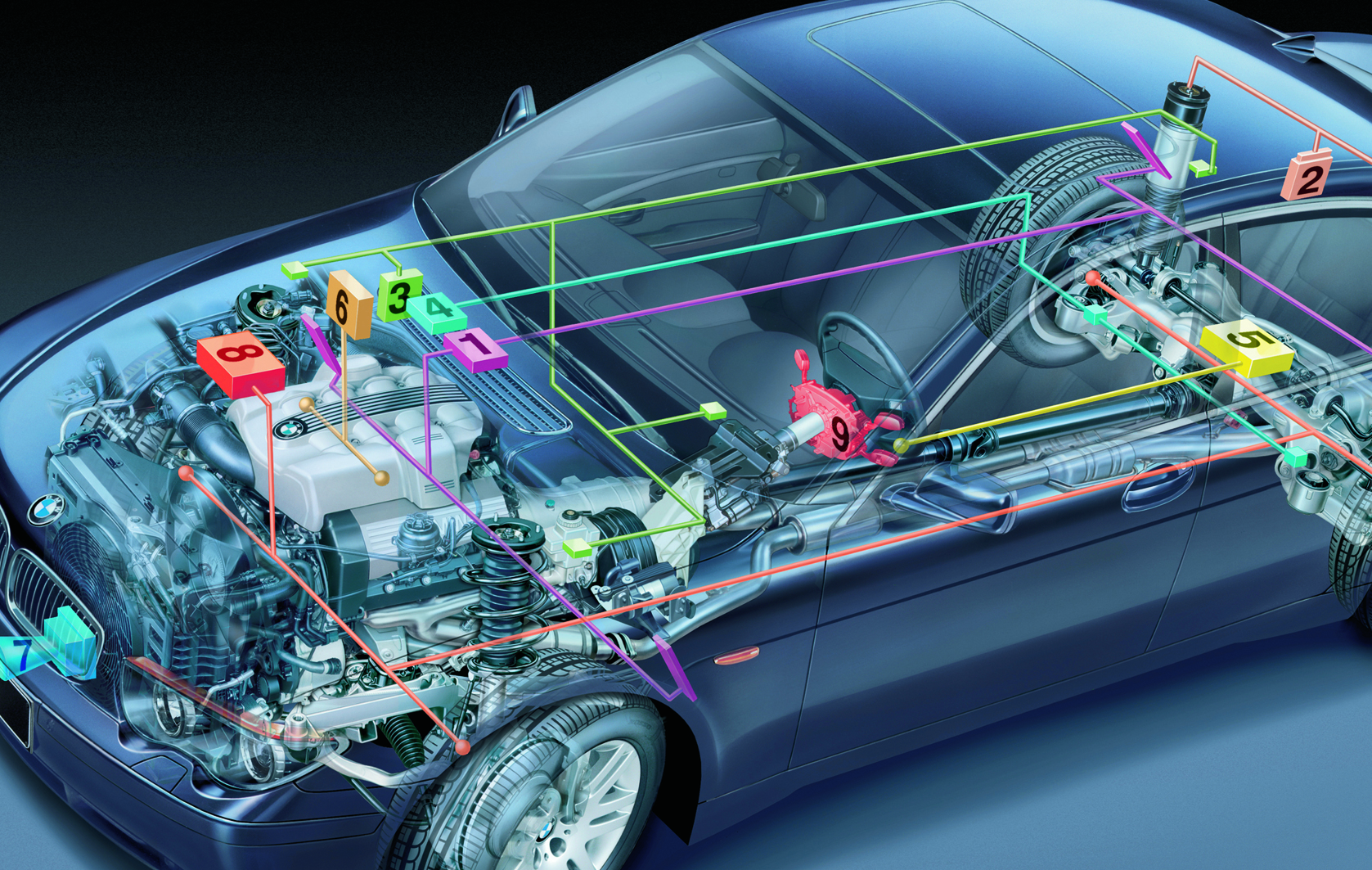

In the intricate symphony of a modern vehicle, countless components work in harmony to ensure safety, performance, and driver comfort. Among these, automotive control cables are the unsung heroes, silently facilitating critical functions like braking, accelerating, gear shifting, and even opening doors and hoods. While the automotive industry increasingly embraces electronic "x-by-wire" systems, mechanical control cables remain indispensable for their reliability, cost-effectiveness, and robust performance in numerous applications. As global vehicle production continues to expand and the aftermarket thrives, the Automotive Control Cable Market is maintaining a steady and crucial trajectory.

This blog delves into the dynamics of the global Automotive Control Cable Market, offering an analytical perspective on its current valuation, growth projections, key segments, and the pivotal drivers and trends shaping its future, with a special focus on India's burgeoning automotive landscape.

The market is commonly segmented by:

By Raw Material

- Steel

- PVC Compound

- Copper Rods

By Product Range

- Single Core Cable

- Multi Core Cable

By Cable Type

- Clutch Cable

- Bowden Cable

- Throttle Cable

- Speedometer Cable

- Steering Control Cable

By End User

- Motorcycles

- Passenger Car Cable

- Light Commercial Vehicle

- Heavy Commercial Vehicle

Market Size and Growth: Stability Amidst Evolution

The automotive control cable market is expected to register a CAGR of 6.9% during 2023–2031. The evolution of advanced technologies and the introduction of high-end vehicles will likely remain a key trend in the market.

Key Market Trends: Beyond the Mechanical

- Lightweighting and Durability: Automakers are constantly seeking ways to reduce vehicle weight to improve fuel efficiency and, for EVs, extend range. Control cable manufacturers are responding by developing lighter yet equally durable materials (e.g., using advanced polymers or optimizing steel wire designs) and innovative construction techniques to enhance lifespan and performance.

- Hybrid and Electric Vehicle (EV) Adaptation: While "x-by-wire" systems reduce the number of traditional mechanical cables in some areas of EVs, control cables still find applications in new areas such as battery compartment access, HVAC flap controls, charging interface mechanisms, and seating adjustments. The shift to EVs thus represents an evolution in application rather than a complete displacement.

- High-Performance and Precision Cables: As vehicles become more sophisticated, there's a demand for control cables that offer higher precision, smoother operation, and reduced friction. This drives innovation in lubrication, inner wire coatings, and casing materials to ensure optimal performance, particularly in critical functions like gear shifting.

- Aftermarket Dominance and Digital Channels: The aftermarket segment continues to be a significant revenue generator, driven by the sheer volume of vehicles on the road and the necessity of periodic cable replacement. The increasing digitization of spare parts sales, including online platforms, is making aftermarket components more accessible globally.

- Integration with ADAS and Autonomous Systems: While some view "x-by-wire" as a threat, the increasing complexity of advanced driver-assistance systems (ADAS) and autonomous driving technologies still requires robust mechanical backups or complementary cable systems for certain functions, ensuring fail-safe operations and enhanced overall vehicle reliability.

Market Growth Relatable FAQs:

- Q: How does the ongoing increase in global vehicle production directly influence the Automotive Control Cable Market?

- A: Every new vehicle manufactured, regardless of propulsion type, requires a range of control cables for essential functions like braking, acceleration, gear shifting, and various auxiliary controls. Therefore, a rise in global vehicle production directly translates to an increased demand for control cables from OEMs, serving as a fundamental market driver.

- Q: What is the significance of the "aftermarket" segment for the Automotive Control Cable Market's sustained growth?

- A: Automotive control cables are wear-and-tear components with a finite lifespan, requiring periodic replacement due to continuous use, friction, and environmental exposure. The vast global fleet of existing vehicles creates a constant and recurring demand for replacement cables, ensuring a stable and continuously growing aftermarket segment for manufacturers.

- Q: How do advancements in "lightweighting" technologies impact the Automotive Control Cable Market, especially with the rise of EVs?

- A: Automakers prioritize lightweighting to improve fuel efficiency in ICE vehicles and extend the range of EVs. Control cable manufacturers are adapting by developing lighter materials and designs for cables (e.g., advanced polymers, optimized steel), ensuring their continued relevance and contribution to overall vehicle efficiency, thereby supporting market evolution.

- Q: Is the shift towards "electronic x-by-wire systems" a significant threat or an evolutionary challenge for the Automotive Control Cable Market?

- A: While x-by-wire systems replace some mechanical linkages, they are more of an evolutionary challenge than an existential threat. Mechanical cables retain advantages in cost, reliability, and simplicity for many functions. Furthermore, new applications arise in EVs and ADAS for specific mechanical or hybrid cable systems (e.g., emergency backups, latch mechanisms), leading to market adaptation rather than decline.

- Q: How do stringent global safety standards and the demand for enhanced driver comfort influence the development and demand for automotive control cables?

- A: Strict safety regulations necessitate highly reliable and durable braking, clutch, and gear shift cables. Simultaneously, consumer demand for smoother, more precise vehicle operation drives innovation in cable design (e.g., low-friction coatings, improved materials) to enhance driver comfort and responsiveness, leading to a demand for higher-quality and more advanced control cables.

Conclusion: Essential Threads in the Automotive Fabric

The Automotive Control Cable Market, though often overlooked, remains an indispensable pillar of the global automotive industry. Its resilience, driven by the sheer volume of vehicle production and the perpetual demand from the aftermarket, underscores its fundamental importance. As the automotive world continues its journey towards electrification and advanced automation, control cables will adapt, evolve, and continue to play their silent yet critical role, connecting drivers to their machines and ensuring the smooth, safe, and reliable operation of vehicles worldwide.