The global manufacturing landscape is undergoing a major transformation, driven by the increasing adoption of advanced technologies such as additive manufacturing (AM), lightweight materials, and automation. Among the most promising areas in this evolution is the FDM (Fused Deposition Modeling) composite large-size tooling market, which is gaining traction across industries including aerospace, automotive, marine, defense, and energy. By enabling faster, cost-effective, and more flexible tooling production, FDM composite solutions are reshaping how companies approach manufacturing and prototyping at scale.

This article provides a comprehensive analysis of the FDM composite large-size tooling market, exploring its growth drivers, challenges, key applications, technological advancements, and future outlook.

Understanding FDM Composite Large-Size Tooling

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies that extrudes thermoplastic filaments layer by layer to build complex parts. In recent years, the incorporation of high-strength composite materials—such as carbon-fiber reinforced polymers—has expanded the capabilities of FDM beyond prototyping into large-size tooling applications.

Large-size tooling refers to the molds, jigs, fixtures, and other industrial tools required for manufacturing large components, such as aircraft fuselage parts, wind turbine blades, or automotive body panels. Traditional tooling methods, including CNC machining and casting, are expensive, time-consuming, and inflexible. In contrast, FDM composite large-size tooling offers:

-

Lightweight and durable tools with enhanced mechanical strength.

-

Reduced production cost and time compared to traditional methods.

-

Greater design flexibility, enabling the production of complex geometries.

-

Rapid iteration for design validation and prototyping.

Discover how the FDM Composite Large-Size Tooling Market is changing with key trends and forecasts. Access the report:

https://www.databridgemarketresearch.com/reports/global-fdm-composite-large-size-tooling-market

Market Growth Drivers

The FDM composite large-size tooling market is expanding rapidly due to several factors:

1. Aerospace and Defense Industry Adoption

Aerospace companies are early adopters of FDM composite tooling to produce lightweight and heat-resistant tools for manufacturing advanced aircraft components. With the growing demand for fuel efficiency, airlines and OEMs are prioritizing composite materials, which in turn drives demand for composite-based tooling solutions.

2. Automotive Lightweighting Trends

The automotive industry is under increasing regulatory pressure to reduce carbon emissions. This has spurred the adoption of lightweight materials and advanced manufacturing processes. FDM composite tooling enables automakers to reduce lead times in producing large components such as body panels, dashboards, and chassis parts.

3. Cost Reduction and Efficiency

Traditional tooling can take months to produce and requires significant investment. FDM reduces lead times from weeks to days and lowers costs by up to 70%. This efficiency is highly attractive for manufacturers in competitive markets.

4. Advancements in Composite Materials

Recent innovations in high-performance thermoplastics such as ULTEM™, PEKK, and PEEK, reinforced with carbon or glass fibers, have enhanced the structural integrity and heat resistance of FDM-based tools, making them suitable for demanding industrial applications.

5. Sustainability Goals

Additive manufacturing reduces material waste compared to subtractive methods, aligning with global sustainability initiatives. Composite tooling further enhances the lifespan of tools, reducing resource consumption.

Key Market Challenges

While the outlook for FDM composite large-size tooling is promising, the market also faces several challenges:

-

High initial investment in large-scale industrial 3D printers.

-

Material limitations in terms of maximum temperature resistance compared to metals.

-

Post-processing requirements such as surface finishing to meet aerospace or automotive standards.

-

Knowledge gap and skills shortage among manufacturers transitioning from conventional to additive manufacturing.

Applications of FDM Composite Large-Size Tooling

The market’s potential is evident in its wide range of applications across industries:

1. Aerospace and Defense

-

Composite lay-up molds for wings, fuselage, and interior components.

-

Jigs, fixtures, and drilling guides used in assembly.

-

Lightweight tooling for rapid prototyping and testing.

2. Automotive

-

Prototypes and molds for large body panels and structural parts.

-

Assembly jigs, fixtures, and inspection tools.

-

Custom tooling for low-volume or specialty vehicles.

3. Marine Industry

-

Molds for producing boat hulls, decks, and other large composite structures.

-

Customized fixtures for repair and retrofitting.

4. Energy Sector

-

Tooling for wind turbine blades and composite energy storage systems.

-

Fixtures for oil and gas pipelines and infrastructure.

Technological Advancements Driving the Market

Recent innovations are propelling the FDM composite large-size tooling market forward:

-

Large-Format 3D Printers: Printers capable of producing components several meters in size are now available, addressing large tooling needs.

-

Hybrid Manufacturing: Combining FDM with CNC machining allows for both rapid production and high precision.

-

Automation and AI Integration: AI-driven software optimizes print paths, reduces material usage, and improves structural performance.

-

Improved Composite Filaments: Development of high-strength, high-temperature filaments expands tooling applications into harsher environments.

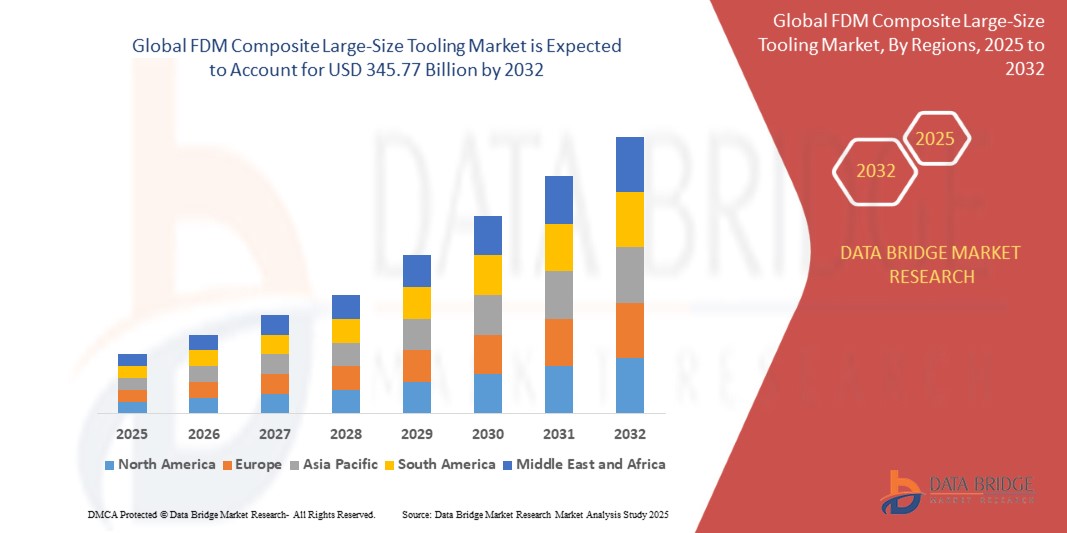

Regional Insights

-

North America dominates the market due to strong aerospace, automotive, and defense industries, with major players like Boeing and Lockheed Martin actively adopting FDM composite tooling.

-

Europe is a key market driven by its automotive giants (BMW, Volkswagen) and aerospace sector (Airbus).

-

Asia-Pacific is witnessing rapid growth, fueled by rising manufacturing activity in China, Japan, and South Korea, alongside government initiatives supporting additive manufacturing.

-

Middle East & Africa and Latin America are emerging markets, gradually adopting advanced tooling technologies in energy and aerospace sectors.

Future Outlook

The future of the FDM composite large-size tooling market looks highly promising:

-

Market Growth: Industry analysts expect double-digit CAGR growth over the next decade, with increasing adoption across multiple verticals.

-

Customization and On-Demand Production: Manufacturers will increasingly adopt FDM tooling for small-batch and custom production runs.

-

Integration with Industry 4.0: FDM composite tooling will align with digital manufacturing ecosystems, enabling end-to-end automation and real-time monitoring.

-

Expansion into New Industries: Beyond aerospace and automotive, sectors such as healthcare (prosthetics and implants), architecture (custom structures), and construction (formworks) are expected to adopt large-size FDM tooling solutions.

Conclusion

The FDM composite large-size tooling market is set to revolutionize manufacturing by offering a faster, more cost-effective, and sustainable approach to tooling production. With rising demand from aerospace, automotive, energy, and marine industries, alongside advancements in composite materials and 3D printing technologies, the market’s growth trajectory is undeniable.

While challenges such as material limitations and high upfront costs remain, ongoing innovations and increasing industry awareness will continue to strengthen market adoption. For manufacturers seeking agility, efficiency, and sustainability, FDM composite large-size tooling is not just an alternative—it is the future of industrial tooling.

Browse More Reports:

Global Aramid Fiber Market

Global Artery Stenosis Drug Market

Global Artificial Intelligence as a Service Market

Global Asset Reliability Management Market

Global Assets Management IOT Market

Global Asteroid Mining Market

Global Attitude and Heading Reference Systems (AHRS) Market

Global Automated Breach and Attack Simulation Market

Global Automated Dispensing Machines Market

Global Automatic Flexible Packaging Machines Market

Global Automation Testing Market

Global Automotive Active Suspension System Market

Global Automotive Cylinder Liner Market

Global Automotive Decorative Exterior Trim Plastics Market

Global Automotive Differential System Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience, which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com