Competitive Analysis of Executive Summary Metal Forming Market Size and Share

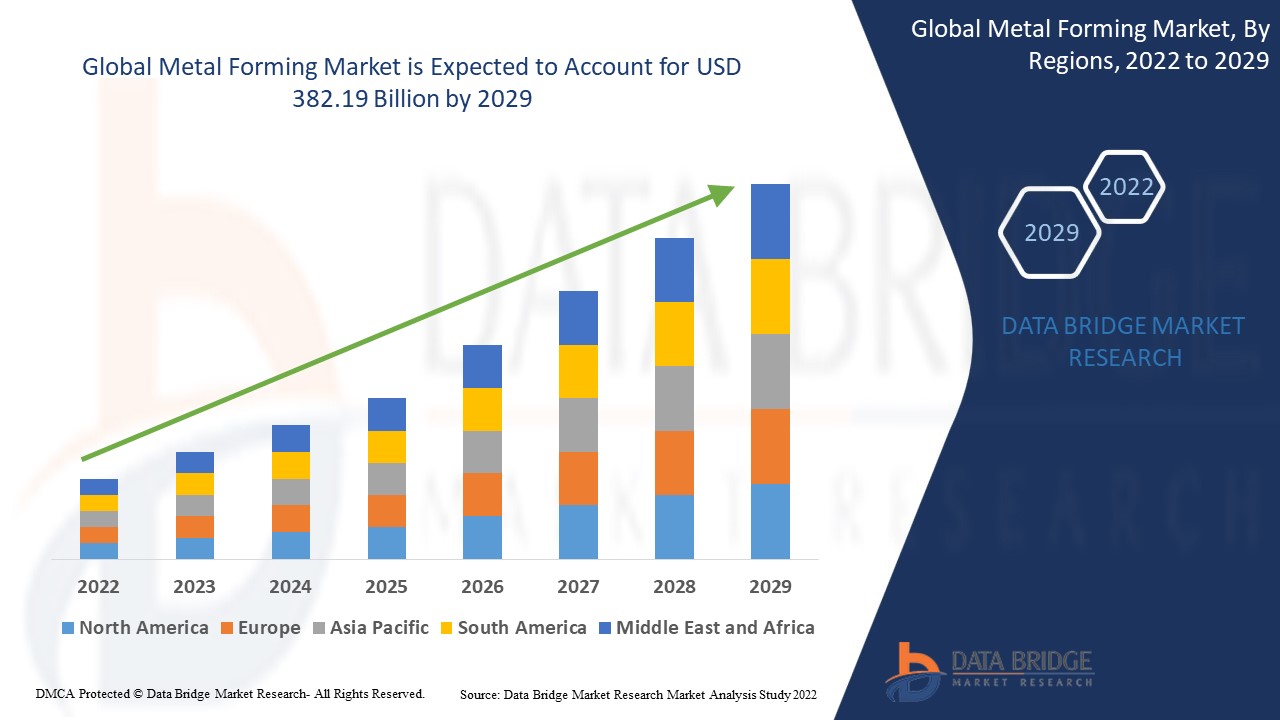

The market Global Metal Forming Market was valued at USD 247.65 billion in 2023, is projected to grow at a CAGR of 7.50% and reach USD 441.68 billion by 2031.

Global Metal Forming Market report comprises of data that can be quite essential when it comes to dominate the market or making a mark in the market as a new emergent. The statistics are represented in graphical format in this report for a clear understanding on facts and figures. The report provides insights which help to have a more precise understanding of the market landscape, issues that may impinge on the Metal Forming Market industry in the future, and how to position specific brands in the best way. Analysis and discussion of important industry trends, market size, and market share estimates are mentioned in the wide-ranging Metal Forming Market business report.

Market research analysis and insights covered in the reliable Metal Forming Market report are very considerate for the businesses to make better decisions, to develop better strategies about production, Market, sales and promotion of a particular product and thereby extending their reach towards the success. With the use of outstanding practice models and excellent method of research to generate this report that aids businesses to uncover the greatest opportunities to prosper in the market. While preparing the widespread Metal Forming Market report, no stone is left unturned to consider public demands, competencies and the constant growth of the working industry, vibrant reporting, and high data protection services.

Get the edge in the Metal Forming Market—growth insights and strategies available in the full report:

https://www.databridgemarketresearch.com/reports/global-metal-forming-market

Metal Forming Market Landscape Overview

Segments

- By Technology: Roll Forming, Stretch Forming, Stamping, Deep Drawing, Hydroforming, Others.

- By Metal Type: Steel, Aluminum, Copper, Magnesium, Titanium, Others.

- By End-Use Industry: Automotive, Aerospace, Industrial Machinery, Construction, Electrical & Electronics, Others.

The global metal forming market is segmented on the basis of technology, metal type, and end-use industry. In terms of technology, roll forming is expected to witness significant growth due to its widespread adoption in various industries like automotive and construction. Stretch forming is also projected to grow as it offers advantages such as high strength and design flexibility. The stamping segment is anticipated to maintain a strong position in the market owing to its cost-effectiveness and efficient manufacturing process. Deep drawing and hydroforming technologies are also expected to contribute to the market growth. When it comes to metal type, steel dominates the market due to its high demand in automotive and construction sectors for its durability and strength. Aluminum is gaining traction in aerospace and electrical industries for its lightweight properties. Copper, magnesium, and titanium segments are also projected to show growth due to their specific applications in various end-use industries. In terms of end-use industry, the automotive sector is the largest consumer of metal forming products due to the increasing production of vehicles worldwide. The aerospace industry is also a key driving force in the market due to the demand for lightweight and durable components.

Market Players

- General Electric

- Benteler International

- Magna International

- Tower International

- Aisin Seiki Co. Ltd.

- Toyota Boshoku Corporation

- Kirchhoff Automotive

- Voestalpine AG

- Magna International Inc.

- Haley Aerospace

- Forming Technologies Inc.

Key market players in the global metal forming market are General Electric, Benteler International, Magna International, Tower International, Aisin Seiki Co. Ltd., Toyota Boshoku Corporation, Kirchhoff Automotive, Voestalpine AG, Magna International Inc., Haley Aerospace, and Forming Technologies Inc. These companies are focusing on strategic initiatives such as mergers and acquisitions, product innovations, and partnerships to strengthen their market position and expand their product portfolio to cater to the increasing demand from various end-use industries.

- Bradbury Group (U.K.)

- Formtek Moulding Solutions (South Africa)

- Mestek Machinery (U.S.)

- Avic Manufacturing Technology Institute (China)

- VNT Automotive GmbH (Austria)

- Westway Machinery (Canada)

- Benteler International AG (Germany)

- AES Automotive Company Pvt. Ltd. (India)

- Toyota Boshoku Corporation (Japan)

- Samco Machinery (India)

- Aisin Seiki Co. Ltd (Japan)

- Heck Industries (U.S.)

- Wuhan Huagong, Schuler India Private Ltd. (India)

- Magna International Inc. (Canada)

- Drexler Companies Inc. (U.S.)

- Hirotec Corporation (Japan)

- CIE Automotive (Spain)

The global metal forming market is undergoing significant transformation driven by technological advancements and increasing demand from various end-use industries. One key trend shaping the market is the rising adoption of automation and robotics in metal forming processes to enhance efficiency and precision. Automation allows for higher productivity, reduced labor costs, and improved consistency in product quality, which are crucial factors for manufacturers looking to stay competitive in the market. Robotics are being integrated into metal forming operations to perform repetitive tasks with speed and accuracy, leading to enhanced overall operational efficiency.

Another trend reshaping the metal forming market is the growing focus on sustainability and environmental consciousness. Manufacturers are increasingly adopting eco-friendly practices and materials to minimize their carbon footprint and meet regulatory requirements. This shift towards sustainability is driving the development of innovative metal forming techniques that reduce waste generation, energy consumption, and greenhouse gas emissions. Additionally, the emphasis on recyclability and resource efficiency is prompting metal formers to explore alternative materials and processes that have lower environmental impact without compromising on performance or quality.

Furthermore, the increasing emphasis on product customization and personalization is influencing market players to invest in advanced technologies and tools that enable them to meet evolving customer demands. Customization allows manufacturers to differentiate their products in a competitive market landscape and cater to niche requirements of diverse end-use industries. Metal formers are leveraging digital technologies like 3D modeling, simulation, and virtual prototyping to design and produce bespoke components that align with customer preferences and specifications. This trend is also driving the integration of data analytics and machine learning algorithms to optimize production processes and enhance product quality.

Moreover, the market is witnessing a surge in research and development activities aimed at enhancing material properties, process efficiency, and product performance. Manufacturers are collaborating with academic institutions, research organizations, and technology partners to explore new alloys, coatings, surface treatments, and forming techniques that offer superior mechanical properties, corrosion resistance, and thermal stability. The continuous innovation in materials science and manufacturing processes is paving the way for advanced metal forming solutions that deliver improved functionality, reliability, and longevity across various industrial applications.

In conclusion, the global metal forming market is evolving rapidly in response to changing industry dynamics, technological advancements, and customer preferences. Market players need to stay abreast of these emerging trends and opportunities to stay competitive and capitalize on the growing demand for high-quality, eco-friendly, and customized metal forming solutions. By embracing innovation, sustainability, and digital transformation, manufacturers can position themselves for long-term success and growth in the increasingly competitive metal forming market landscape.The global metal forming market is experiencing a significant transformation driven by technological advancements and shifting industry trends. One of the key trends shaping the market is the increasing adoption of automation and robotics in metal forming processes. Automation is enabling higher productivity, reduced labor costs, and improved product quality consistency, which are essential factors for manufacturers aiming to enhance efficiency and competitiveness. Robotics are being integrated into operations to perform repetitive tasks with speed and accuracy, contributing to overall operational efficiency improvements for metal formers.

Another notable trend in the metal forming market is the growing emphasis on sustainability and environmental consciousness. Manufacturers are increasingly turning towards eco-friendly practices and materials to reduce their carbon footprint and comply with regulatory standards. This shift towards sustainability is fostering the development of innovative metal forming techniques that minimize waste generation, energy consumption, and greenhouse gas emissions. Additionally, the focus on recyclability and resource efficiency is driving the exploration of alternative materials and processes with lower environmental impact while maintaining performance and quality standards.

Furthermore, the market is witnessing a rising demand for product customization and personalization, prompting market players to invest in advanced technologies to meet evolving customer requirements. Customization allows manufacturers to differentiate their products and cater to the specific needs of diverse industries. By leveraging digital tools such as 3D modeling, simulation, and virtual prototyping, metal formers can design and produce bespoke components aligned with customer preferences. This trend is also driving the integration of data analytics and machine learning algorithms to optimize production processes and enhance product quality.

Moreover, research and development activities are accelerating in the metal forming market to improve material properties, process efficiency, and product performance. Collaborations with research institutions and technology partners are leading to the exploration of new alloys, coatings, and forming techniques that offer enhanced mechanical properties, corrosion resistance, and thermal stability. Continuous innovation in materials science and manufacturing processes is paving the way for advanced metal forming solutions that deliver superior functionality, reliability, and longevity across various industrial applications.

In conclusion, the global metal forming market is dynamic and evolving, driven by technological innovation, sustainability initiatives, customization demands, and research advancements. Market players need to adapt to these emerging trends to stay competitive and meet the increasing demand for high-quality, environmentally friendly, and tailor-made metal forming solutions. Embracing innovation, sustainability, and digital transformation will be crucial for manufacturers to position themselves for long-term success and growth in the evolving market landscape.

Study the company’s hold in the market

https://www.databridgemarketresearch.com/reports/global-metal-forming-market/companies

Custom Question Framework for Global Metal Forming Market Reports

- What does the most up-to-date research indicate about Metal Forming Market size?

- What is the expected yearly market acceleration?

- What are the major subdivisions discussed in the Metal Forming Market report?

- Which businesses lead in competitive positioning?

- What innovations or launches have made an impact lately?

- What global and local markets are under review?

- Where is the fastest regional expansion occurring?

- Which country will likely be at the forefront by Metal Forming Market size?

- Which region has the strongest historical Metal Forming Market base?

- What region or country shows the highest compound growth rate?

Browse More Reports:

Global Car Batteries Market

Global Cardiovascular Needles Market

Global Cargo Drones Market

Global Carmine Market

Global Cartilage Regeneration Market

Global Cannabidiol (CBD) Skin Care Market

Global Chemical Soil Testing Market

Global Cloud Gaming Market

Global Cocoa Products Market

Global Colour Cosmetics Market

Global Commercial Drones Market

Global Confectionery Processing Equipment Market

Global Contract Furniture and Furnishing Market

Global Crop Protection Products Market

Global Customer Data Management Market

Global Hardware in the Loop Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com