Stainless steel hot rolled coil gives your project the perfect blend of durability and adaptability right from the start. When you rely on Jianglinsteel, you tap into our decades of experience crafting high-quality coil that meets stringent industrial demands. In the following sections, I’ll walk you through the entire journey—from material science and production to real-world applications and why making the switch benefits your bottom line.

What Is Stainless Steel Hot Rolled Coil?

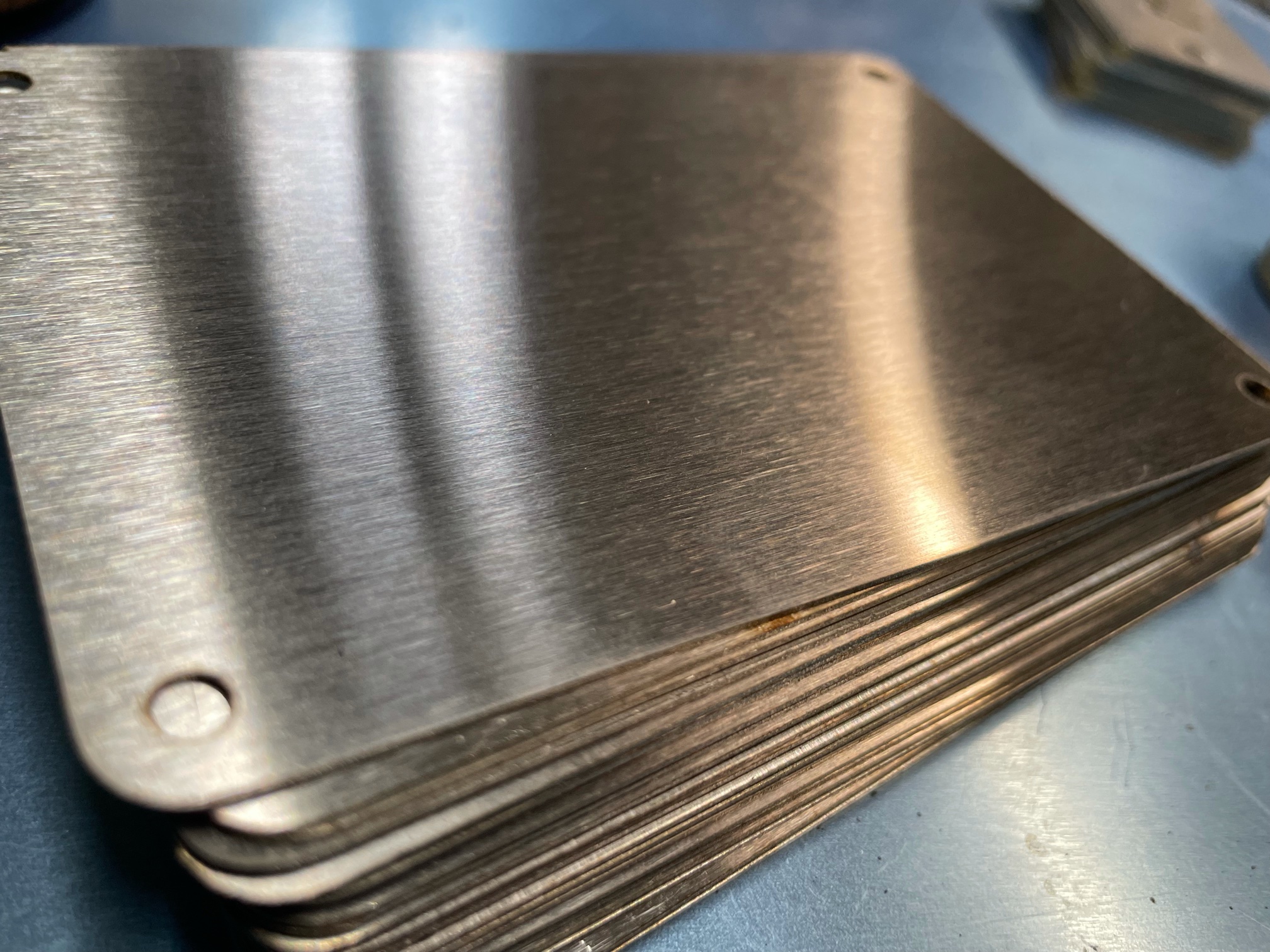

Stainless steel hot rolled coil refers to stainless steel processed by rolling at high temperatures—typically above 1,000°F. This method leads to coils possessing:

-

Superior structural strength

-

Excellent surface finish

-

More flexible dimensions

-

Cost savings compared to cold-rolled steel

At Jianglinsteel, we specialize in grades like 304 and 316, each tailored for performance in distinct environments.

Why Transition to Hot Rolled Coil?

-

Cost Efficiency

High-temperature rolling demands less mechanical processing. This efficiency translates into lower costs for you. -

Enhanced Workability

Hot rolled coil remains malleable and easy to shape. Fabricators appreciate its forgiving nature during bending, welding, or cutting. -

Robust Strength

Heat-driven refinement of the steel’s grain structure boosts toughness. This coil stands strong under stress and heavy use. -

Practical Thickness Range

Ranging from 2mm to 25mm or beyond, hot rolled coil fits heavy-duty applications with ease. -

Surface Durability

Though not mirror-smooth, the slightly scaled finish resists corrosion and handles most industrial settings perfectly.

What Are the Common Grades and Specifications?

Understanding the available grades and specs helps align coil choices with project goals.

Popular Stainless Steel Grades

-

304/304L: This versatile alloy offers strong corrosion resistance, especially in indoor or mildly corrosive conditions.

-

316/316L: With added molybdenum, 316 thrives in marine, chemical, or pharmaceutical applications due to superior corrosion protection.

Coil Dimensions & Tolerances

Manufactured to precise sizes to fit industrial needs:

-

Thickness: 2 mm – 25 mm+

-

Width: 100 mm – 2,000 mm

-

Coil Weight: 3 T – 20 T

-

Tolerances follow ISO/NFA standards to guarantee conformity.

At Jianglinsteel, we customize dimensions to your exact requirements—no bulk compromise.

How Does Jianglinsteel Manufacture These Coils?

Our production process ensures every coil we deliver exceeds expectations.

-

Melting & Casting

We melt high-purity raw materials and cast them to create billets with excellent structural integrity. -

Reheating

Billets undergo reheating to over 1,100°C, making them soft and easy to work with. -

Hot Rolling

Precision rolling mills reduce thickness gradually, maintaining uniformity throughout. -

Cooling & Coiling

Controlled cooling builds structural resilience. Then, we coil steel into transport-ready units. -

Inspection & Packaging

We conduct dimensional and surface checks. After passing inspection, we wrap coils in protective packaging for optimum safety.

Where Are These Coils Used?

Stainless steel hot rolled coils serve diverse sectors due to their robust nature:

Construction & Infrastructure

-

Structural beams

-

Bridge components

-

Reinforcement plates

Industrial Machinery

-

Gear housings

-

Machine frames

-

Base plates

Energy & Oil Industries

-

Pipelines

-

Platform structures

-

Offshore rigs

Manufacturing

-

Welding bases

-

Press parts

-

Heavy-duty racks

Add welding, bending, or further machining to customize each coil for your needs.

What Benefits Will Jianglinsteel Bring You?

-

High Strength

Our coils undergo consistent rolling and heat treatment, yielding long-lasting structural integrity. -

Tight Manufacturing Tolerances

We maintain minute thickness variations and remove surface flaws so your installation fits right the first time. -

Competitive Pricing

Thanks to streamlined production, you receive excellent value without sacrificing performance. -

Customization

Need odd sizes or special grades? Just ask. We tailor coils to suit your projects precisely. -

Fast Delivery

With in-house mills and strategic shipping partnerships, we fulfill orders quickly and reliably.

How to Choose the Right Coil for Your Project?

Pick the Correct Grade

For everyday environments, go with 304. If you’re up against salt spray or chemicals, 316 proves smarter.

Nail Down Thickness & Width

Heavy structural work demands thicker gauges; fabrication pieces need nimble profiles.

Confirm Coil Weight

Check your handling equipment’s capacity. Oversized coils might create logistics challenges.

Surface & Tolerance Needs

Factory environments often accept hot rolled surfaces. But if final finish matters, communicate early to prep for finishing steps.

Contact Jianglinsteel for a quote customized to your precise demands.

How Do You Store and Handle Coils?

-

Use Proper Equipment

Heavy-duty coil hooks, C-hooks, and spreader beams ensure secure lifting. -

Store Smart

Keep coils dry, on stable platforms, and covered to reduce oxidation risk. -

Maintain Track Records

Note grade, weight, heat numbers—the basics for traceability. -

Avoid Bending & Scratches

Don’t lean pallets or tools against coils. Keep edges protected.

What Quality Assurance Measures Does Jianglinsteel Use?

-

Material Testing

We verify chemistry and mechanical strength at every step. -

Surface Inspections

Trained operators assess coil appearance and detect hidden cracks or faults. -

Dimensional Monitoring

Thickness gauges provide real-time feedback to ensure consistency. -

Third-Party Certification

On request, we arrange inspections from bodies like SGS or BV.

What Is the Environmental Impact?

Our hot rolling process helps minimize greenhouse gas emissions by cutting down mechanical working. We also recycle process water and reuse offcuts, making us more sustainable. Plus, stainless steel is 100% recyclable—adding an eco advantage.

What’s the ROI of Choosing Us?

-

Reduced Waste

Consistent coil quality means less scrap and rework. -

Speedier Fabrication

You save time in welding, bending, and finishing stages. -

**Minimized Maintenance

**Stainless steel resists corrosion—cutting down on long‑term repairs and replacements. -

Environmental Compliance

Utilize eco-friendly materials while strengthening your corporate responsibility image.

How to Get Started with Jianglinsteel

-

Send Us Your Specs

Provide grade, thickness, width, coil weight, and quantity. -

Get a Fast Quote

We offer transparent pricing within 24–48 hours. -

Approve & Schedule

Once you sign off, we start production or pull from inventory. -

Track Your Order

We share fabrication updates and shipping details in real-time. -

Receive & Validate

Accept your coils, perform checks, and start work confidently.

FAQs About Stainless Steel Hot Rolled Coil

Q: Can I weld hot rolled coil easily?

Yes, familiar techniques like TIG or MIG work smoothly—just prep your edges correctly.

Q: Should I expect scale or rough areas?

Yes, minor scaling is normal on surface with hot rolled coil. Most applications tolerate it; final finishing removes any blemishes.

Q: What heat numbers exist on coils?

Heat numbers mark the batch origin. Use them to trace quality and consistency.

Q: How long can I store coils?

If you store them in dry, covered spaces, they’ll last years. Outdoors exposure risks surface rust.

Conclusion

Stainless steel hot rolled coil from Jianglinsteel delivers the strength, flexibility, and cost‑effectiveness your industrial or construction project needs. Our meticulously controlled manufacturing, strict quality standards, and sustainable approach make us the ideal supplier.

Get in touch today—request a quote and partner with a stainless steel provider you can trust.