In the realm of modern manufacturing, precision, speed, and efficiency are paramount. Traditional welding methods, while effective for many applications, often fall short when it comes to intricate designs, delicate materials, or high-volume production with stringent quality demands. This is where Laser Welding Machines step in, offering unparalleled accuracy, minimal heat input, and superior weld quality, making them indispensable across a diverse range of industries.

This blog post provides a global market-oriented analysis of the Laser Welding Machine Market, delving into its substantial valuation, consistent growth trajectory, key technologies and applications, and the pivotal trends shaping its future.

The Segmentation

By Technology

- Fiber

- Solid-State

- Co2

By End-user

- Automotive

- Electronics

- Medical

- Aerospace

- Jewelry

- Packaging

Market Size and Growth: Precision on the Rise

This market size is projected to reach US$ xxx billion by 2031, and it is estimated to grow at a CAGR of xx% from 2023 to 2031.

Key Market Trends: Smarter, Faster, More Flexible

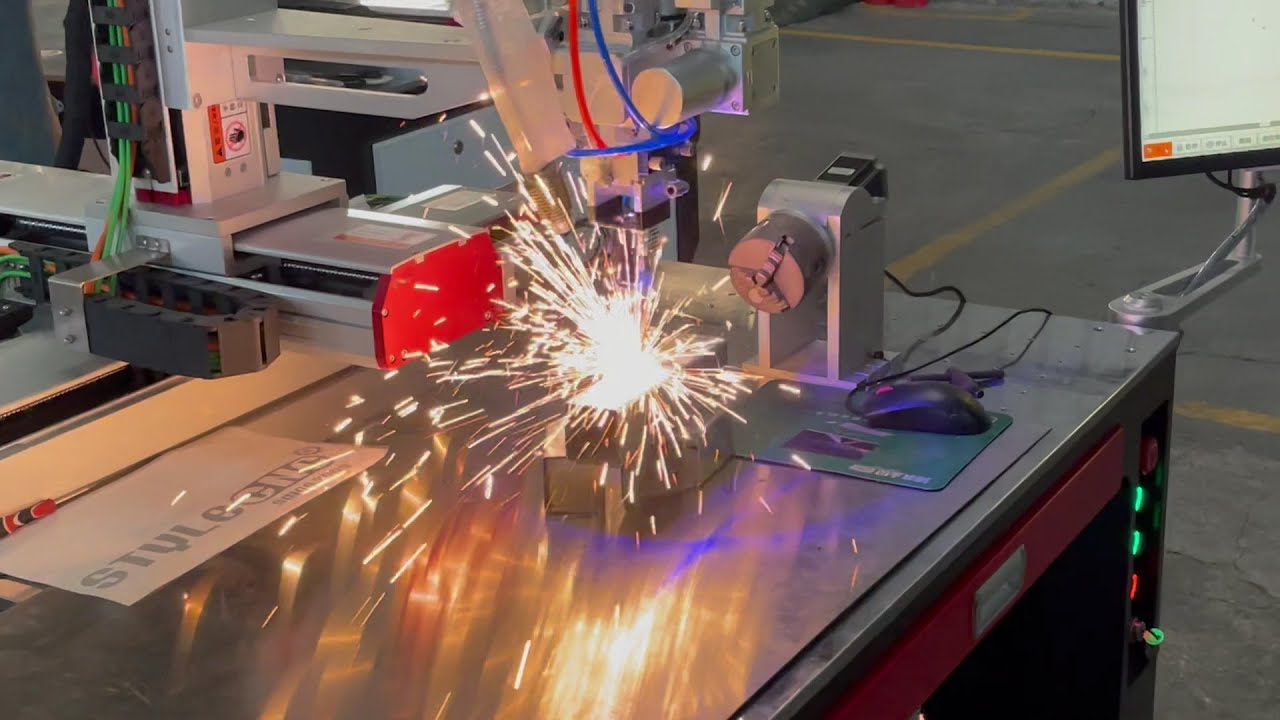

- Automation and Robotics Integration: The seamless integration of laser welding machines with industrial robots and collaborative robots (cobots) is a dominant trend. This enables fully automated production lines, reduces human error, increases throughput, and addresses labor shortages. Robotic laser welding held a significant market share in 2024.

- Handheld Laser Welding Machines: These portable, versatile, and easy-to-use machines are gaining significant traction, especially for smaller businesses and repair applications. The handheld laser welding machine market is projected to grow at a remarkable CAGR of 22.4% from 2024 to 2033.

- Hybrid Laser-Arc Welding: This combines the precision of laser welding with the gap-bridging capabilities and cost-effectiveness of arc welding. Hybrid systems offer faster welding speeds, deeper penetration, and improved material tolerance, expanding the range of applications. This segment is expected to show significant CAGR.

- Increasing Power Output and Advanced Beam Shaping: Developments in laser technology are leading to higher power output systems (above 5 kW, which is projected to grow fastest) and sophisticated beam shaping techniques. These innovations allow for faster processing, deeper penetration, and the ability to weld new or challenging materials with superior quality.

- Integration of AI and Machine Learning: AI and ML are being embedded into laser welding systems for real-time process monitoring, predictive maintenance, automated parameter optimization, and defect detection. This enhances efficiency, precision, and overall weld quality, paving the way for self-optimizing manufacturing processes.

Market Growth Relatable FAQs:

- Q: How is the "global rise in electric vehicle (EV) production" a major driver for the Laser Welding Machine Market?

- A: EV manufacturing heavily relies on laser welding for critical components like battery cells, modules, and packs due to the need for high-strength, leak-proof, and electrically conductive welds on highly reflective materials like copper and aluminum. As EV adoption surges, so does the demand for specialized laser welding solutions.

- Q: Why is "fiber laser technology" dominating the laser welding machine market?

- A: Fiber lasers offer superior beam quality, high energy efficiency (lower operating costs), and exceptional flexibility. Their ability to precisely weld a wide range of materials, including highly reflective metals used in modern electronics and EVs, makes them the preferred choice for many industrial applications.

- Q: How does the trend of "automation and robotics integration" impact the growth and capabilities of laser welding machines?

- A: Integrating laser welding with robots (both industrial and collaborative) enables fully automated, high-volume production lines. This significantly increases welding speed, consistency, and precision while reducing reliance on manual labor, addressing workforce shortages, and improving overall manufacturing efficiency.

- Q: What challenges related to "initial investment cost" does the Laser Welding Machine Market face, especially for smaller businesses?

- A: Laser welding machines, particularly high-power and automated systems, represent a significant capital investment. This can be a barrier for Small and Medium-sized Enterprises (SMEs). However, the rise of more affordable handheld laser welding machines and increasing accessibility are helping to mitigate this challenge and expand the user base.

- Q: How do "stringent quality and safety standards" in industries like medical devices and aerospace drive the adoption of laser welding?

- A: Industries like medical and aerospace demand extremely high precision, reliability, and weld integrity where defects can have critical consequences. Laser welding's ability to produce clean, strong, and highly repeatable welds with minimal heat distortion makes it the preferred technology for meeting these rigorous quality and safety requirements, ensuring product performance and regulatory compliance.

Conclusion: The Future is Fused by Light

The Global Laser Welding Machine Market is at the forefront of the advanced manufacturing revolution. Its ability to deliver unmatched precision, speed, and versatility is making it an indispensable tool for industries worldwide. As technological advancements continue to drive innovations in automation, AI integration, and material processing, laser welding machines will only become more sophisticated and widely adopted. From the automotive factories of Pune to the high-tech electronics plants globally, the future of fabrication is increasingly being fused by the power of light.